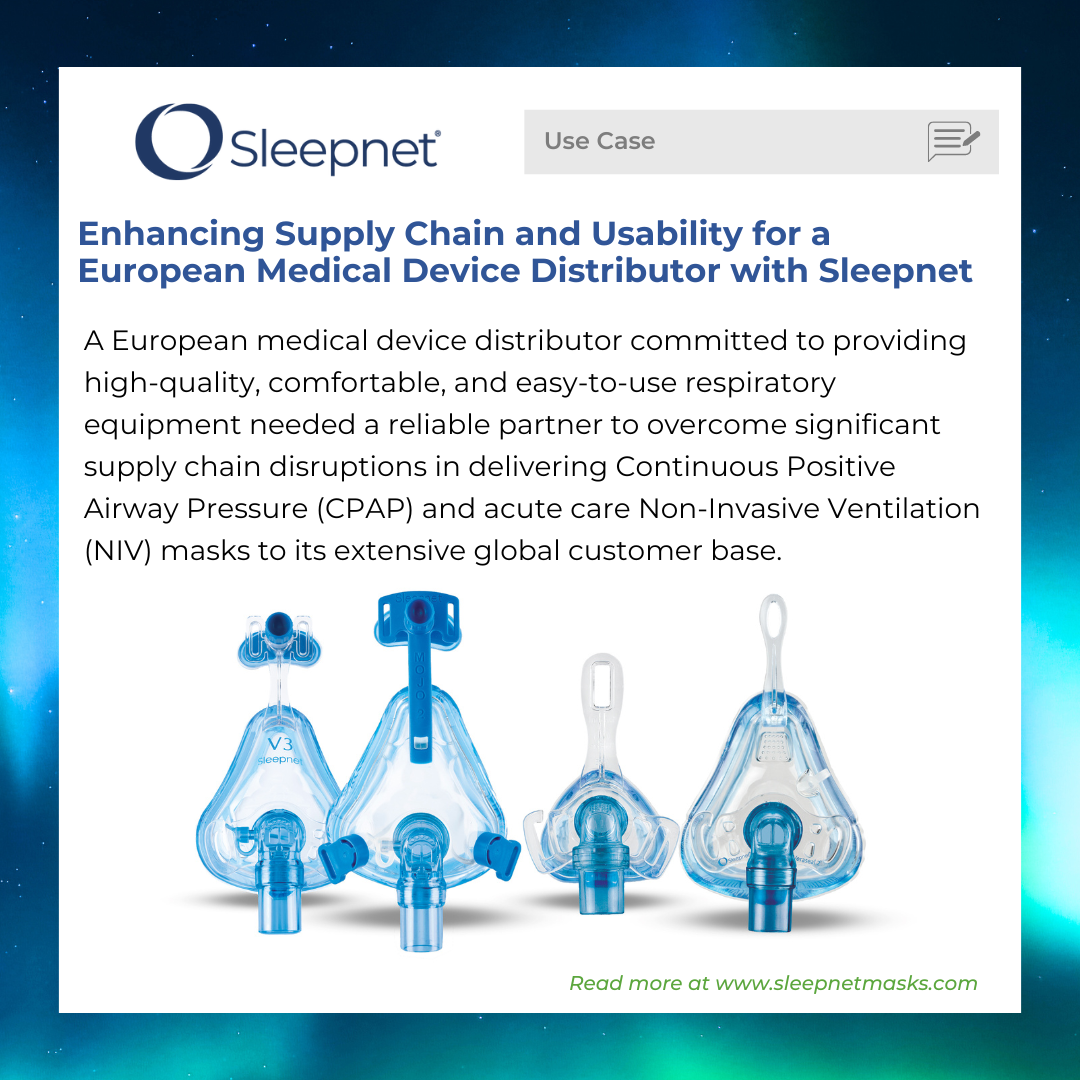

Use Case: Enhancing Supply Chain and Usability for a European Medical Device Distributor with Sleepnet

Background

A European medical device distributor committed to providing high-quality, comfortable, and easy-to-use respiratory equipment needed a reliable partner to overcome significant supply chain disruptions in delivering Continuous Positive Airway Pressure (CPAP) and acute care Non-Invasive Ventilation (NIV) masks to its extensive global customer base. The company also faced regulatory and service problems with some of its existing partners. This use case delves into how Sleepnet effectively collaborated with the European distributor to address these critical issues.

The Problem: Delays, Recalls, and Training

European medical supply distributors face specific challenges when dealing with Non-Invasive Ventilation (NIV) or Continuous Positive Airway Pressure (CPAP) masks. These challenges are particularly prominent due to the specialized nature of these medical devices and the regulatory and logistical complexities involved. The European medical device distributor in this use case was grappling with a series of problems:

- Regulatory Compliance: NIV and CPAP masks fall under stringent regulatory requirements, especially under the EU Medical Device Regulation (MDR). Distributors must ensure that these masks meet all safety, performance, and quality standards before they can be marketed. These standards include ensuring that the masks have the necessary CE markings and that all related documentation, such as clinical data and risk assessments, is thorough and compliant with MDR guidelines. Due to the high costs and complexity of complying with the new EU Medical Device Regulation, many medical device manufacturers withdrew products from the EU market or halted production (Euro News 2023; EU commission approves delay in medical devices law to avert shortages).

- Supply Chain Disruptions: Global supply chain disruptions have heavily impacted the production and distribution of NIV and CPAP masks. These masks require specialized materials and components, some of which may be in short supply or subject to delays due to manufacturing bottlenecks or transportation issues. The COVID-19 pandemic exacerbated these challenges, as demand for respiratory support devices surged, leading to shortages and logistical hurdles in sourcing and delivering these products (Medical Plastics New 2022; Overcoming Supply Chain Disruptions in Medical Device Manufacturing). Frequent delays and inconsistencies in receiving CPAP and NIV masks from existing suppliers disrupted the company’s ability to meet customer demand.

- Training and Support: Distributors often need to provide extensive training and support to healthcare providers and patients on the correct use of NIV and CPAP masks. This training includes guidance on mask fitting, maintenance, and troubleshooting. As these masks are essential for patient care, especially for those with chronic respiratory conditions, improper use can lead to ineffective treatment or patient discomfort, making training a critical aspect of distribution (Oxford Medical Education 2024). In this case, the distributor sought a mask supplier that could provide extensive product training and resources.

The Solution: Partnership with Sleepnet

Recognizing the need for a dependable solution, the distributor partnered with Sleepnet, a company renowned for its high-quality respiratory masks and robust supply chain.

Implementation

- Needs Assessment and Customization: Sleepnet conducted a thorough assessment of the distributor’s requirements, focusing on the quality, training, and supply chain management. They tailored their offerings to meet these specific needs.

- Supply Chain Optimization: Sleepnet leveraged its well-established logistics network in the US and Europe to ensure a reliable and consistent supply of CPAP masks. Specifically, Sleepnet’s presence and warehouse in Europe allowed for reduced shipping costs and times. They also improved market access within Europe while enhancing overall inventory management and efficiency for the distributor, who had multiple points of distribution.

- Personalized Service & Training: Sleepnet offered personalized service and customized training to properly instruct the distributor’s technicians and providers on how to use and fit Sleepnet’s NIV and CPAP masks. Sleepnet provided ongoing in-person training as well as online product resources such as videos, user manuals, and quick start guides.

- Quality Assurance: Sleepnet provided high-quality CPAP masks known for their comfort, fit, and durability. Rigorous quality control processes ensured that every mask met the highest EU standards, reducing return rates and enhancing customer satisfaction.

Results

The collaboration between the distributor and Sleepnet led to several improvements:

- Reliable Supply Chain: The distributor experienced a dramatic reduction in supply chain disruptions. Sleepnet’s efficient logistics, European distribution center, and inventory management system ensured that CPAP and NIV masks were always available when needed, enhancing the distributor’s ability to meet customer demand.

- Improved Product Knowledge and Acceptance: Technicians and providers became more knowledgeable and confident in using and fitting Sleepnet’s NIV and CPAP masks, leading to better patient outcomes. Thanks to effective training, proper mask fitting and usage resulted in fewer returns and complaints.

- Improved Quality and Customer Satisfaction: Sleepnet’s high-quality CPAP masks received positive feedback from customers for their comfort and ease of use. The new masks led to higher compliance and customer satisfaction, strengthening the distributor’s reputation for quality. Technicians reported higher levels of satisfaction due to the enhanced support and resources, reducing the learning curve and improving overall service quality.

Conclusion

The strategic partnership between the European medical device distributor and Sleepnet successfully addressed critical challenges. Sleepnet’s commitment to quality, service, and supply chain reliability provided the distributor with the tools needed to enhance its product offerings and market position. This case study underscores the value of strong partnerships in the healthcare supply chain, demonstrating how innovative solutions can drive success for distributors and their customers.